If the mating gear has more teeth than the pinion that is.

Rack and pinion gear ratio calculation pdf.

Unlike ball screw sizing which must take into account factors such as characteristic and critical speeds end bearing considerations and the effects of preload in addition to basic thrust force and drive torque calculations rack and pinion drive sizing is primarily based on three factors.

The smallest number of teeth on a spur pinion and gear one to one gear ratio which can exist without interference is np.

Gear termi nology this is one of the easiest guides on gears.

Generally gear rack and pinion are collectively called rack and pinion.

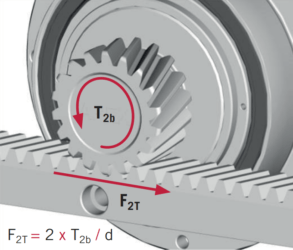

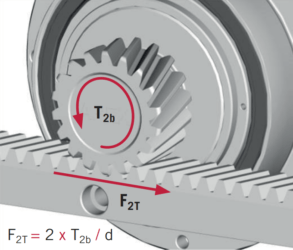

Gear racks are utilized to convert rotating movement into linear motion.

A gear rack has straight teeth cut into one surface of a square or round section of rod and operates with a pinion which is a small cylindrical gear meshing with the gear rack.

Mprn with standard clearance and rack in 6h25 quality pinion in 7e25 quality.

11 7 rack and pinion august 15 2007 28 rack and pinion august 15 2007 29 internal spur gear provides more compact drives compared to external gears they provide large contact ratio relatively less sliding and hence less wear compare to external gears august 15 2007 30 internal spur gear.

The quality of the rack and pinion drive depends on its installation situation in the machine.

For example pinion with 18 teeth is mounted on a motor shaft and is meshed with a larger gear that has 54 teeth.

An important principle is that you realize that the calculation and selection rack pinion gearbox and motor is done by trial and error.

Gear ratio calculation.

Hardness of the rack.

The results of the design shows that weight of new rack and pinion gearbox is 20 less than the oem rpg with nearly 40 reduction in the cost achieving the desired steering ratio.

The force the rack sees.

Rack dimensions in q5 the rack can be delivered as 1 m or 0 5 m as standard.

You can calculate the gear ratio by using the number of teeth of the driving gear a k a.

In q6 the rack can be delivered as 2 m 1 m or 0 5 m as standard.

Gear ratio you can think of gear ratio as a multiplier on speedand a divider on torque.

The inputgear divided by the number of teeth of the driven gear a k a.

During operation the pinion makes three complete revolutions for every single revolution of the larger gear.

You have a good chance that you have to do the calculations again with other parameters such as the diameter of the pinion or the quality read in this case.