Hex head bolt installation design tolerances.

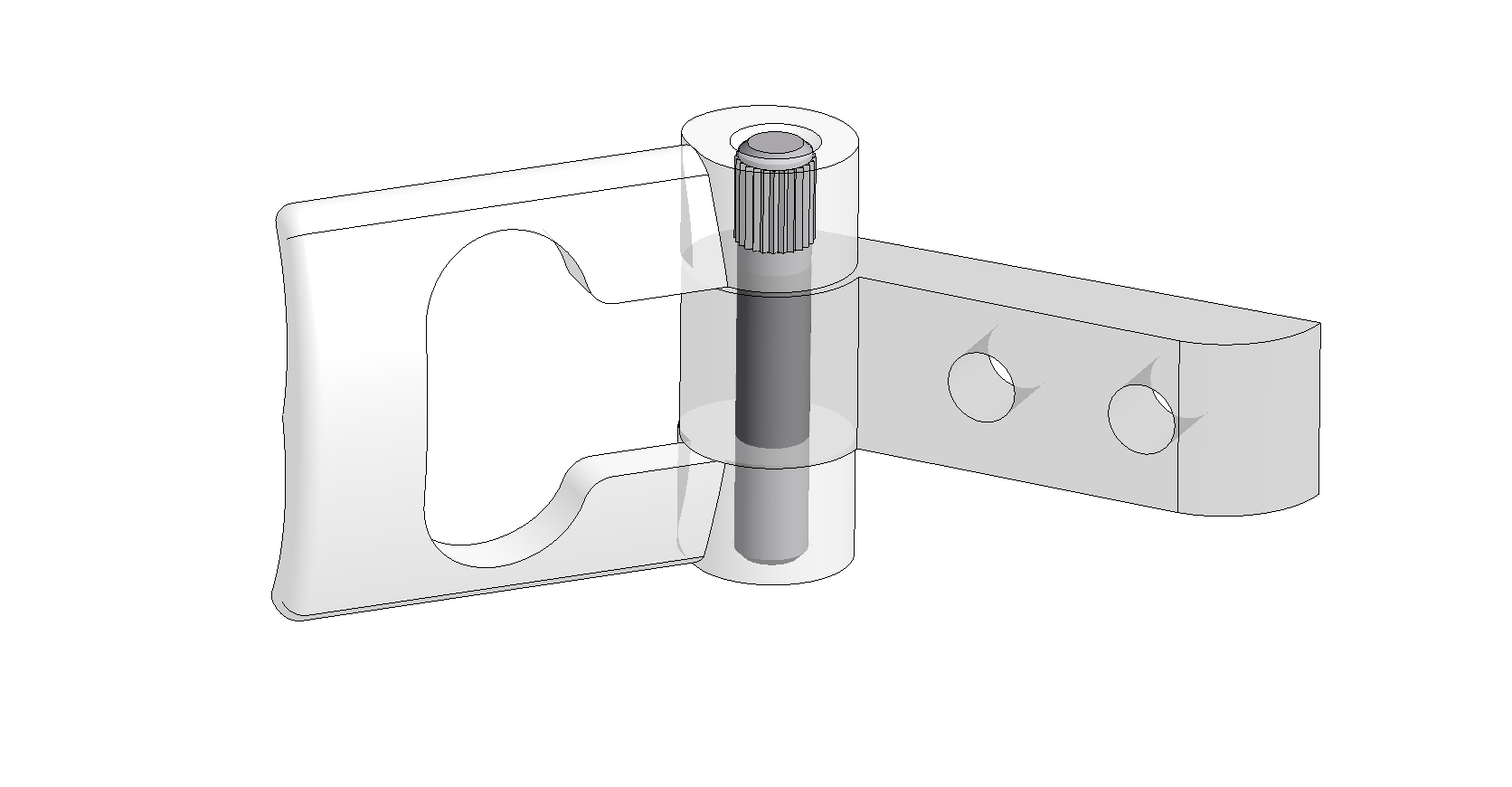

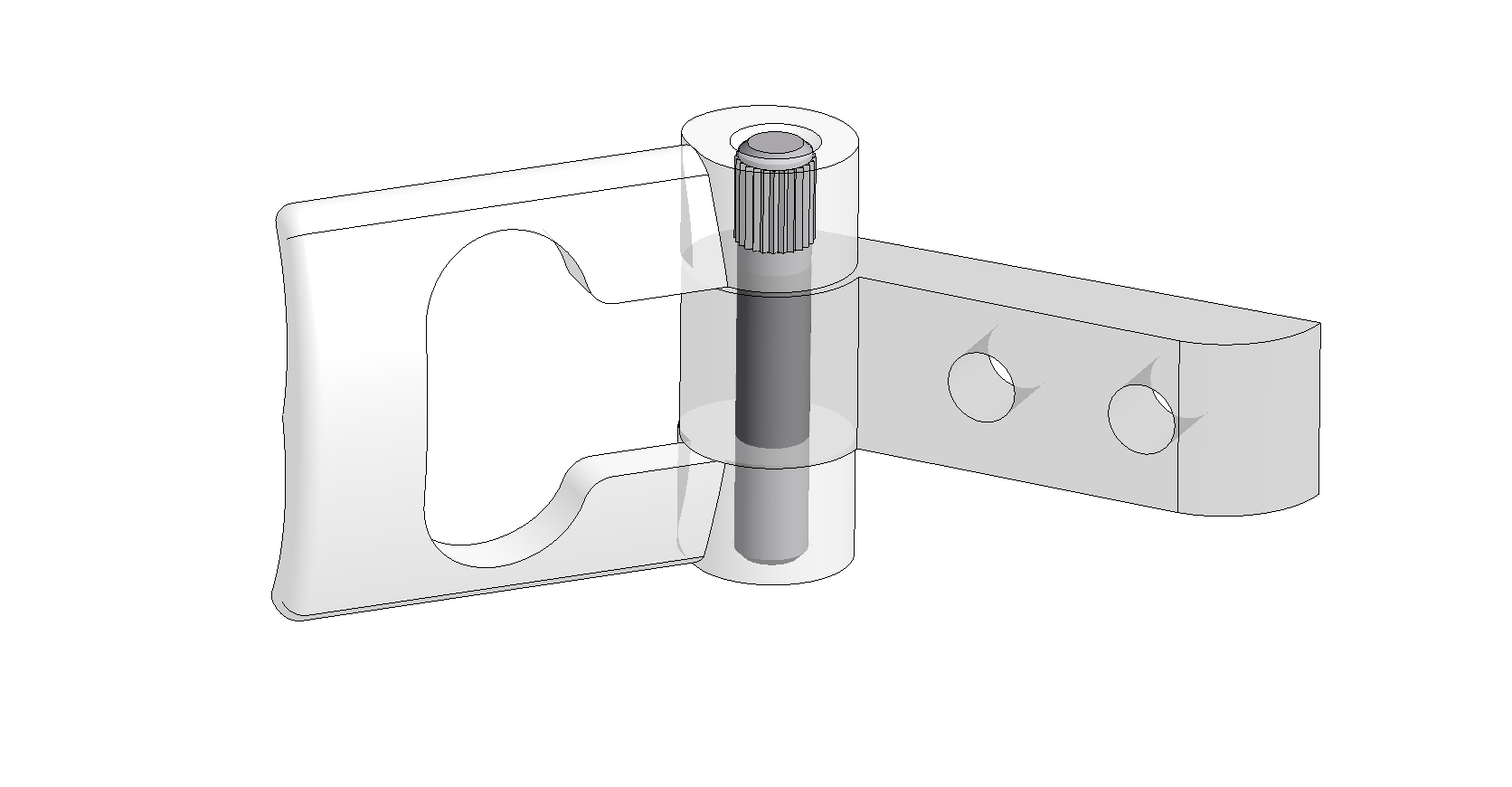

Press fit pins sheet metal.

Studs pins for sheet metal.

All technical data provide permanent male threads in thin metallic and non metallic sheets used when components have to be positioned before final attachment installation into drilled or punched hole is quick and permanent with any standard press.

Each direct acting press features a ram that produces up to 8 5 kilonewtons of force and a stroke up to 80 millimeters.

For the traditional use of press fits where the pins both join and accurately locate the parts better designs use slip fit dowel pins for self locating and bolts to join the parts.

Studs and pins for sheet metal.

The enlarged head diameter reduces stress on the panel and the thicker head allows for a larger hole in the attached panels.

Though press fits have their limitations don t despair.

The clinch design provides high strength in sheets as thin as 031 0 8 mm.

The thfe is recommended for use in steel or aluminum sheets hrb rockwell b scale 85 or less and hb hardness brinell 165 or less.

Slip press fit design tolerances for ansi size dowel pins.

To remove thread a screw or tool into the tapped hole then pull the pin out.

Which results in the sheet metal being thinner on the edges.

One latter company recently asked baltec to customize two da 850 pneumatic presses so they can press fit pins into 40 different height pistons for refurbishing hvac compressors.